Description

Product info

GCR7-910: Max Payload 7kg | Reach 910mm

The next-generation collaborative robot offers a cost-effective solution with a versatile design. It combines a lightweight build, rapid deployment, and ease of operation, ensuring both safety and energy efficiency. Perfect for high-efficiency, low-cost operations in manufacturing environments, this compact robot minimizes space usage while delivering outstanding performance. It is ideal for industries such as 3C (Computer, Communication, and Consumer Electronics) and automotive, driving productivity and efficiency.

Features

Safety

DUCO is equipped with safety features like collision detection, force, and power detection. It is certified by TUV SUD and is the first domestic cobot manufacturer to pass the IEC61508 certification, ensuring safer human-machine collaboration.

Smart

Deep integration of 2D/3D vision

High-sensitivity force sensors and control

Cloud-based robot data monitoring and remote OTA upgrades

One-click deployment of multiple devices and remote data backups

Wide Application

Supports multiple scene software packages such as welding, palletizing, gluing, etc.

Compatible with various peripheral interfaces (DI, DO, A/I, etc.)

Full ecosystem support for diverse application development

Easy Operation

Direct teaching programming, making it easier to use

After just 4 hours of training, users can perform basic programming

Eco

High load-to-weight ratio with power consumption as low as 200W

No need for lubrication oil throughout its lifetime, reducing maintenance costs

Contributes to lower environmental costs and aids in the development of carbon neutrality and carbon peaking goals.

Application

- Polishing

- Painting

- Loading And Unloading

- Palletizing

- Welding

- Gluing

- Screwing

- Assembly

- Quality Inspection

- Material Handling

Specifications

|

Parameter |

GCR7-910 | |

|

Cobot |

Max Payload |

7kg |

| Degree of Freedom |

6 |

|

|

Max TCP Speed |

3.6m/s | |

| Max Straight-line Speed |

1.5m/s |

|

|

Reach |

917mm | |

| Reposition Accuracy |

±0.02mm |

|

|

Power Consumption |

200W | |

| Installation |

Installed in any Direction |

|

|

IP Class |

IP54/IP65 | |

| End I/O Port |

2D, 2DO, EtherCAT, RS485 |

|

|

Robot Package Size |

698x588x450mm | |

| Net/Gross Weight |

22kg/30kg |

|

|

Control Box |

Input Power Supply |

100-240VAC 47-63Hz 10A |

| Communication Interface |

TCP/IP, Modbus/TCP, Profinet(Slave Station), Ethernet/IP(Slave Station), CAN, RS485 |

|

|

I/O Interface |

16DI, 16DO (PNP, 24V/Max 500mA), Among which 8DI/8DO can be configured |

|

|

Size |

410x306x292mm | |

| Weight |

13.6kg |

|

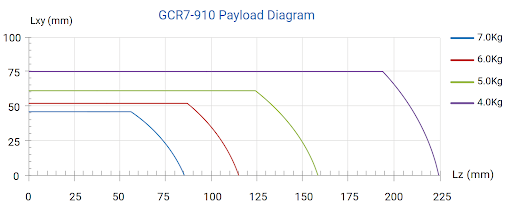

Payload Diagram

Work Space

EOAT Flange

Control System

The controller is used to control the robot’s operations such as loading and unloading, grasping, polishing, handling, welding, gluing and oiling, as well as realizing the input and output control. The latest DUCO controller has compact size while taking into account the safety and flexibility, and has better performance in the field of human cooperation. It can be fully compatible with multiple series of robots, and also can be independently applied to automatic control systems

Reviews

There are no reviews yet.