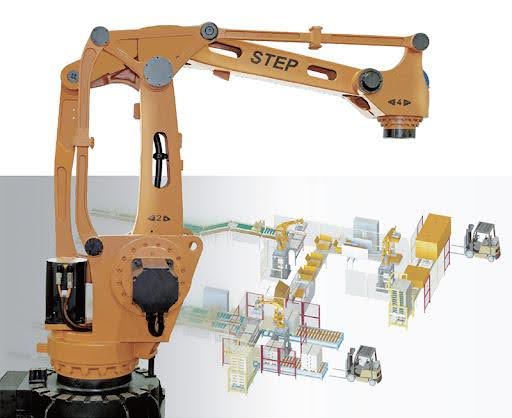

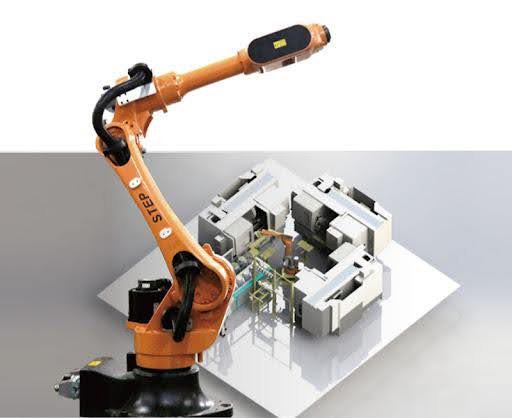

Palletizing robots, also known as Robotic Palletizing systems, are advanced automation solutions that are becoming increasingly popular in modern manufacturing plants. This technology not only optimizes the process of loading and unloading goods but also brings numerous outstanding benefits such as increased productivity, enhanced precision, improved workplace safety, and cost savings. In the context of Industry 4.0 and globalization, the application of palletizing robots has become a crucial factor in helping businesses enhance their competitiveness and efficiently meet market demands.

1. Benefits of Palletizing Robots

Integrating palletizing robots into production lines provides several practical advantages for businesses:

1.1. Increased Productivity

Robots can operate continuously 24/7 without the need for breaks, accelerating production timelines and enabling timely responses to market demands. With high processing speeds, robots can handle large volumes of goods in a short period, far surpassing the productivity of manual labor.

1.2. High Precision

Programmed meticulously and equipped with advanced sensors, palletizing robots perform uniform and accurate operations, minimizing errors. This ensures product quality and optimizes storage space on pallets, helping to save warehouse space.

1.3. Workplace Safety

Robots replace humans in physically demanding tasks such as lifting and stacking goods, reducing the risk of workplace accidents and protecting employee health. An improved working environment also enhances job satisfaction and workforce efficiency.

1.4. Cost Savings

Although the initial investment in robots can be high, in the long run, this technology significantly reduces labor costs while increasing production efficiency. This leads to sustainable economic benefits, especially for large-scale manufacturing enterprises.

1.5. Application Flexibility

Palletizing robots can be programmed to handle a wide range of products, from lightweight items like food and beverages to heavy industrial goods such as automotive components. This flexibility allows robots to easily adapt to diverse production requirements.

2. Real-World Applications of Palletizing Robots

Palletizing robots are widely deployed across various industries, delivering superior efficiency in automating production and logistics processes:

2.1. Food and Beverage Industry

In food and beverage manufacturing plants, robots assist in neatly and safely stacking cartons, bottles, and food packaging onto pallets. For example, in soft drink production lines, robots can stack hundreds of bottles per minute, speeding up production and ensuring quality during transportation.

2.2. Pharmaceutical Industry

In the pharmaceutical sector, palletizing robots are used to handle medicine boxes and bottles with precision, meeting stringent hygiene and safety standards. This technology minimizes the risk of product damage and ensures the integrity of goods throughout the transportation process.

2.3. Logistics Industry

In warehouses and distribution centers, palletizing robots optimize loading and unloading processes, reducing processing time and enhancing logistics efficiency. They can automate the entire workflow from receiving goods, stacking them on pallets, to preparing for shipment, saving time and resources.

2.4. Automotive Manufacturing

In automotive plants, robots are utilized to handle heavy components such as engines, gearboxes, and large parts. The use of robots not only reduces manual labor but also accelerates production, ensuring timely supply for assembly lines.

2.5. Other Industries

Beyond the sectors mentioned, palletizing robots are also used in electronics, chemicals, and construction materials manufacturing. Depending on specific requirements, robots can be customized to handle goods of various sizes, weights, and shapes.

3. Technologies Supporting Palletizing Robots

To achieve optimal performance, palletizing robots are often integrated with advanced technologies such as:

Vision Systems: These help robots identify the position, size, and shape of products, enabling more precise loading and unloading operations.

Robotic Arms: Designed for flexibility, these arms can handle a variety of goods, from lightweight to heavy items.

Programming Software: This allows for the adjustment of stacking processes according to production needs, ensuring flexibility and efficiency.

4. Importance in Industry 4.0

In the era of Industry 4.0, palletizing robots are not just automation tools but also strategic assets that help businesses optimize production and logistics. This technology promotes sustainable development by reducing waste, improving efficiency, and enhancing working conditions. With continuous advancements in artificial intelligence and robotics, palletizing robots will become smarter and more adaptable, opening up new opportunities for the manufacturing industry.

Conclusion Palletizing robots have proven to be a vital tool in enhancing the competitiveness of manufacturing enterprises. With their superior benefits in productivity, precision, safety, and cost-effectiveness, this technology is not just a trend but an essential solution in today’s world. As technology continues to evolve, palletizing robots promise to deliver even greater value, shaping a modern and sustainable manufacturing industry.

Leave a Reply