1. BOT AMR – A new push for smart production

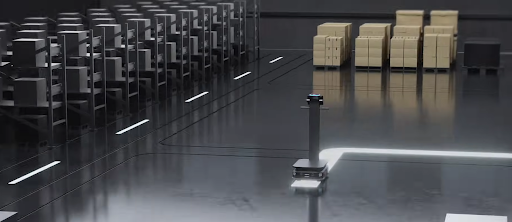

- In the era of automation and digital transformation, Robot AMR (Autonomous Mobile Robot) is emerging as a breakthrough technology, helping businesses optimize operations, reduce labor costs, and increase productivity.

- So what is AMR? Why are modern factories transforming to integrate AMR into their production lines?

2. What is Robot AMR? Why is it an inevitable solution in smart warehouses?

2.1. What is Robot AMR?

Robot AMR (Autonomous Mobile Robot) is a type of mobile robot capable of moving and navigating in a working environment without the need for fixed paths or constant human supervision. This is a significant advancement compared to traditional automated systems such as AGV (Automated Guided Vehicle).

The biggest difference of AMR lies in its ability to move: Thanks to the integration of advanced sensor technologies such as LiDAR, 3D cameras, radar, and intelligent navigation algorithms (SLAM), AMR robots can:

- Select the shortest and safest route to complete tasks.

- Avoid collisions with fixed obstacles such as shelves, machine stations, etc.

- React flexibly to moving objects such as people, forklifts, other robots…

2.2. AMR’s strengths surpass older technologies?

While other automation systems (such as AGV) also support internal transport, only AMR truly offers flexibility, rapid adaptation to continuously changing warehouse environments, and the ability to operate independently, even in complex conditions.

2.3. When connected to the MES system, AMR can:

- Automatically calculate optimal routes in real-time.

- Optimize the process of picking, warehousing, and delivery.

- Improve overall operational productivity and efficiency.

2.4. What can AMR do in the warehouse?

Robot AMR can handle most internal logistics tasks such as:

- Transporting goods between areas within the warehouse or factory.

- Picking goods according to orders.

- Delivering goods internally to the production line or packaging area.

- Sorting and classifying goods according to pre-defined logic.

Furthermore, AMR can also work in hazardous or dangerous areas where humans have difficulty accessing, contributing to improved labor safety.

3. Types of AMR Robots in Warehouse Systems

In modern warehouse and factory systems, transporting, sorting, and handling goods are the first stages to be automated due to their repetitive and time-consuming nature. This is when Robot AMR demonstrates its power, helping businesses free up personnel, reduce errors, and increase operating speed.

3.1. AMR for transporting and sorting goods

Automating the internal transport process not only helps reduce the workload for personnel but also ensures continuity, accuracy, and high efficiency throughout the entire operating chain.

Popular AMR solutions include:

- Roller conveyors

- Tilt trays

- Cross-belt sorters

Each AMR system is designed to handle different types of goods with varying weights, shapes, and transport requirements – from heavy pallets to small boxes.

3.2. AMR supports the order picking process

Order preparation is one of the most costly activities in warehouse operations, not because of complex skill requirements, but because of the time employees spend moving a lot, searching for and selecting goods in a large space.

Robot AMR helps solve this problem by:

- Reducing travel time from area to area.

- Self-locating and accurately finding the location of goods.

- Working synchronously with the MES system.

3.3. Advantages of AMR robots in warehouse systems

The benefits of using AMR mobile robots in the warehouse:

- Reduce personnel costs.

- Increase productivity.

- More orders are completed.

- Fewer errors in order preparation, and therefore, fewer returned orders.

- Ensuring safety for workers, as AMR robots can perform strenuous tasks and can work in hazardous, dangerous.

Leave a Reply