Description

Product info

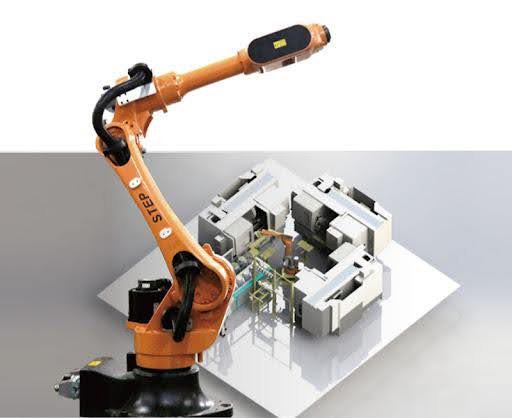

SA Series robots are compact, small and lightweight, ideal for welding applications due to their high stability to finish welding jobs. It can realize high welding-path accuracy, considerably reduce welding cycle-time, and extend the lifetime of tubes and cables. In addition, SA Series robots can fit in narrow working spaces and can be floor mounted, inverted or on the wall at any angle.

Features

- Small size

- Light weight

- High running speed

- High position repeat accuracy

- Good welding reliability

Application

- Arc welding, cutting

Stability improves welding quality which ensures uniformity

Improve productivity and 24 hours continuous production

Improve labor’s working condition, long term operation in harmful condition

Reduce requirements for operation technique

Shorten the period of remodel change, reduce the relevant equipment cost

Realize bulk article of welding automation

Save floor space

- Material Handling, palletizing

More flexible, more stable, less energy consumption

High performance of moving stuff

Exceptionally long run time

Fixed automation

Robot Software System

- Basic Function:

Security protection

User management

Engineering, program and variable management

Tools and coordinate teaching and management

Point/automatic moving position checking

Speed setting and checking

Manual/automatic/external switch

- Advanced Function:

PLC function

Arc welding function

Palletizing function

Additional axis

Bending function

- Palletizing Function

The project uses the palletizing function and external coordinate tracking function of the software, achieving a fully automatic assembly line. One robot can move with the assembly line, meanwhile, the other does the palletizing.

- Welding Function

The arc welding function contains locating, arc swinging, tracking and multilayer and multi-channel function so that it can achieve a very high accuracy

- Bending Function:

Long/short plate bending, combination bending is available, bending precision < 0.5mm.

Main parameters: Sensor or sensorless, bending port number, bending board thickness, bending machine slot width, bending angle, bending speed, delay distance, falling distance, return distance and speed, return delay distance, reference coordinate etc.

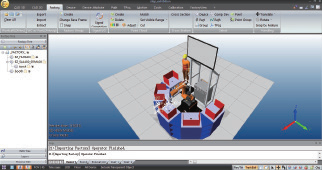

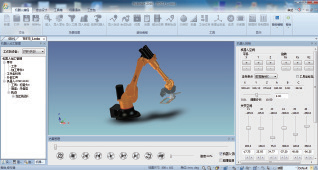

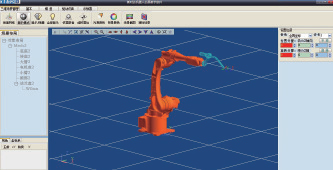

Offline Simulation Teaching Pendant

STEP robots are supported by many off-line programming companies. Off-line programming and simulation functions are available.

- Supported Softwares

DMworks

PTP, LIN, CIRC, WLIN, WCIRC, Arcon, Arcoff, TOOLS, REFSYS, LP, GOTO, WAITTIME, ARCSET;

Welding simulation

Casting trajectory generation

RobotArt

PTP, LIN, Tool, refsys, dyn

Casting trajectory generation and simulation

RobotMaster

Matching STEP’s model and language

Robot holds the tools to cast or engrave

StepRobStudio

STEP developed simulation and off-line programming software

Reviews

There are no reviews yet.